Everything You Need to Know About

Arc Flash Resistant Gloves

Arc Flash related injuries

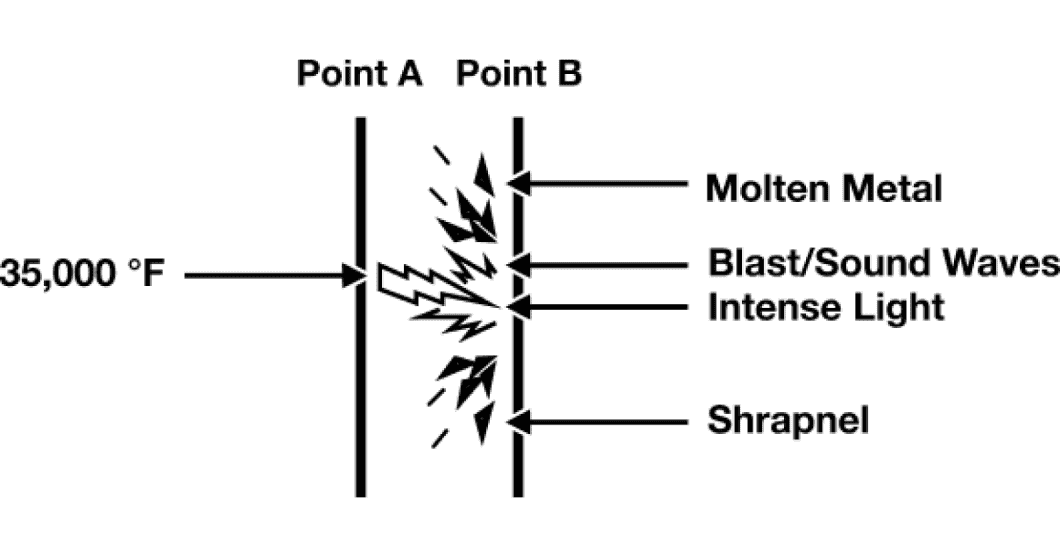

An arc flash occurs when there is a sudden release of electrical energy between two conductors, causing an explosion. It is a serious hazard in industries such as electrical utilities, construction, oil & gas, and manufacturing, where workers are working around high voltage switches and grounding gear, panel boards, switchboards, and transformers. Arc flash related injuries can be extremely dangerous and lead to severe burns, eye damage, hearing loss, and can even be fatal. This is why, it is essential for workers to have head-to-toe protection including hand protection, arc flash- and flame-resistant clothing, safety helmets, and face shields.

Arc flash-resistant gloves offer incidental protection in case there is an arc flash. They are designed to limit the extent of burn injury by resisting heat and flame exposure to the wearer’s hands.

Arc Flash related injuries

An arc flash occurs when there is a sudden release of electrical energy between two conductors, causing an explosion. It is a serious hazard in industries such as electrical utilities, construction, oil & gas, and manufacturing, where workers are working around high voltage switches and grounding gear, panel boards, switchboards, and transformers. Arc flash related injuries can be extremely dangerous and lead to severe burns, eye damage, hearing loss, and can even be fatal. This is why, it is essential for workers to have head-to-toe protection including hand protection, arc flash- and flame-resistant clothing, safety helmets, and face shields.

Arc flash-resistant gloves offer incidental protection in case there is an arc flash. They are designed to limit the extent of burn injury by resisting heat and flame exposure to the wearer’s hands.

What you will learn

- Underlying forces that causes an arc flash

- How arc flash rated gloves protect a worker’s hands

- Common arc flash-resistant materials used to manufacture safety gloves

- Safety standards and tests used to verify the arc flash ratings in gloves

Forces at work in arc flash-resistant gloves

To understand how arc flash-resistant gloves protect workers’ hands, we first need to understand what an arc flash is.

An arc flash occurs when an electrical current jumps between two points (from one conductor to another) due to a difference in potential energy (difference in the amount of energy between two points). This creates a blast of heat and energy. It usually occurs around industrial grade breakers and electrical boxes where there is a lot of energy transferred and where there is a chance of an electrical jump (arc) that can explode. For this reason, arc flash-resistant gloves are made with materials that:

- Resist ignition or combustion to avoid catching on fire

- Not sustain or limit the area if the gloves do catch fire

- Minimize the transfer of heat to the hands

Materials used in arc flash-resistant gloves

The most common material used for protection against arc flash hazards is leather due to its inherent fire resistance and durability. However, other materials are also used to manufacture arc flash-resistant gloves.

LEATHER

Leather is inherently fire resistant and a frontrunner to protect against fire. Its solid outer shell provides a natural barrier for flames or heat to penetrate.

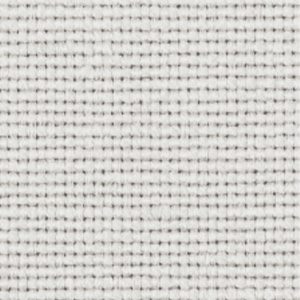

WOOL

Wool is an inherently fire-resistant natural fiber that forms an insulating layer to prevent flames from spreading further. It is not flammable and has a very high ignition temperature, preventing it from easily catching fire. If it does catch fire, the wool burns slowly, and the fibers self-extinguish when the fire source is removed. Wool is often used as an inner liner in leather and knit gloves for extra protection and comfort. Besides being inherently fire-resistant, wool is commonly used as an insulating liner that helps keep hands warm while working in cold temperatures.

COTTON

Cotton is a natural fiber that provides natural heat resistance. However, cotton must be treated with chemicals that resist fire to be fire resistant. Like wool and modacrylic, cotton is most commonly used as a liner in leather and knit gloves for extra protection and comfort against fire hazards.

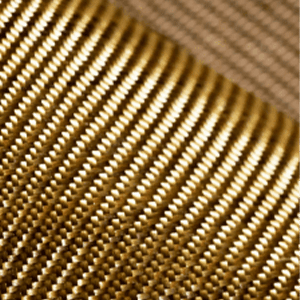

ARAMIDS

Para-aramid and meta-aramid are synthetic fibers that are inherently fire resistant due to their chemical structure. They are often selected because of their superior natural mechanical protection (especially para-aramids) against other hazards like cut and abrasion. Aramids are also frequently paired with leather to improve its natural flame and heat resistance.

MODACRYLIC

Modacrylic is a synthetic fiber that is inherently fire resistant. But, unlike aramids, it lacks any type of mechanical protection. Modacrylic is often blended with other materials (natural or synthetic) to improve mechanical protection and comfort.

NEOPRENE

Neoprene is a synthetic rubber traditionally used for manufacturing chemical gloves and also serve as palm coatings for knit gloves. It is primarily used for its natural high fire resistance against arc flash hazards.

Materials used in arc flash resistant gloves

The most common material used for protection against arc flash hazards is leather due to its inherent fire resistance and durability. However, other materials are also used to manufacture arc flash-resistant gloves.

LEATHER

Leather is inherently fire resistant and a frontrunner to protect against fire. Its solid outer shell provides a natural barrier for flames or heat to penetrate.

WOOL

Wool is an inherently fire-resistant natural fiber that forms an insulating layer to prevent flames from spreading further. It is not flammable and has a very high ignition temperature, preventing it from easily catching fire. If it does catch fire, the wool burns slowly, and the fibers self-extinguish when the fire source is removed. Wool is often used as an inner liner in leather and knit gloves for extra protection and comfort. Besides being inherently fire-resistant, wool is commonly used as an insulating liner that helps keep hands warm while working in cold temperatures.

COTTON

Cotton is a natural fiber that provides natural heat resistance. However, cotton must be treated with chemicals that resist fire to be fire resistant. Like wool and modacrylic, cotton is most commonly used as a liner in leather and knit gloves for extra protection and comfort against fire hazards.

ARAMIDS

Para-aramid and meta-aramid are synthetic fibers that are inherently fire resistant due to their chemical structure. They are often selected because of their superior natural mechanical protection (especially para-aramids) against other hazards like cut and abrasion. Aramids are also frequently paired with leather to improve its natural flame and heat resistance.

MODACRYLIC

Modacrylic is a synthetic fiber that is inherently fire resistant. But, unlike aramids, it lacks any type of mechanical protection. Modacrylic is often blended with other materials (natural or synthetic) to improve mechanical protection and comfort.

Neoprene

Neoprene is a synthetic rubber traditionally used for manufacturing chemical gloves and also serve as palm coatings for knit gloves. It is primarily used for its natural high fire resistance against arc flash hazards.

Materials to avoid when working around arc flash hazards

Thermoplastic materials should be completely avoided when working around arc flash hazards—even in clothing. Thermoplastic materials can melt and graft to your skin and cause serious burn injuries. These include HPPE, nylon, and polyester.

Best practices around arc flash hazardous environments

01

As mentioned earlier, wearing arc flash-rated gloves is only one component of protecting workers against serious injuries. Workers operating equipment where there is a risk of arc flash hazards should be protected head-to-toe to avoid fatal injuries. This includes safety helmets, face shields, arc flash- and flame-resistant clothing, and hand and ear protection.

02

Lockout/tagout procedure. The basic idea behind the lockout tagout method is to set controls to prevent accidents associated with arc flash hazards when the equipment is not in use or under service or maintenance. The procedure requires authorized personnel to close electrical circuits and valves, disconnect power sources, and secure moving parts and more to isolate the equipment from other workers.

03

Minimum safe distance. Workers should follow the minimum safe distance and the arc flash boundary established based on the arc flash risk assessment conducted by your company.

Arc flash resistance safety standards

Industry standards were established with specific testing methods to assign protection levels for safety gloves, including arc flash. These standards were introduced to create a common language for safety managers, distributors, and manufacturers to define protection levels and substantiate protection claims.

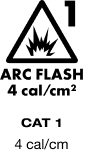

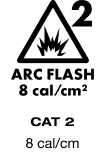

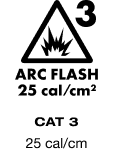

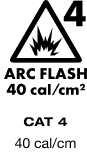

Arc flash testing is conducted under ASTM F1959 and ASTM F2675 standard tests to protect workers in industries who work on or near energized parts or equipment that are capable of generating an arc flash. A key part of the standard establishes CAT categories which define the level of arc rating needed to perform specific hazardous tasks.

Arc flash Categories

Arc flash protection is categorized into 4 groups based on its flame protection (0-4, with 4 being the highest). This is measured by cal / cm2.

Assuming that you have determined that there is a likelihood of an arc flash and have taken additional safety measures to determine the arc flash boundary, gloves and other PPE selection to be used inside of that boundary is determined by the following categories.